Surface processing not only adds functionality but also transforms a product’s size, shape, and weight. It is our desire to create functional and unique surfaces that go above and beyond our customers’ needs, developed using 3D simulations and surface evaluation technologies.

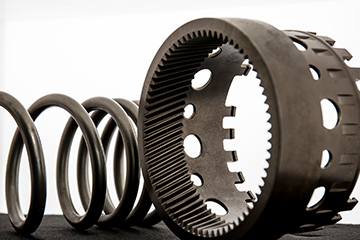

Surface treatment can improve the strength of products. Improved strength leads to products of lighter weight, also resulting in energy savings. Under the name of “strength”, we add safety and energy savings to metal products.

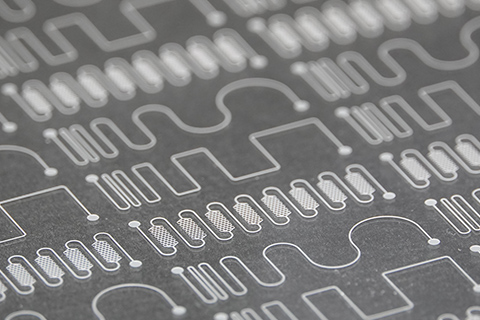

In the future, the electronics and precision parts industries will require even smaller and lighter-weight products. Micro surface processing not only makes this smaller and lighter-weight production possible, it is also a next-generation processing technology that improves productivity.

We provide surface characteristics that can fulfill the functions our customers require, such as smooth surfaces and non-slip surfaces. We help to discover the surface characteristics that bring out the advantages of surfaces of each kind of material.

Removing burrs created during casting with technology that eliminates sharp edges.

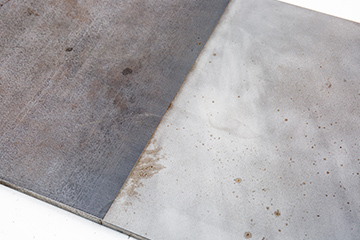

Technology for removing sand from the product’s surface.

Technology for adding textures to the target’s surface.

Technology to create polished surfaces that are glossy and smooth.

Applying stress to the surface to prevent breakages in metallic products.

Technologies that create microscopic grooves and perforations in materials.

Evaluating product surfaces and interior conditions with scanning technologies.

By using a motor to spin blades at high speed, centrifugal force shoots abrasives at a surface. This makes it possible to process wide surfaces efficiently.

Abrasives are shot from a nozzle using pressurized air. This is useful for localized processing.

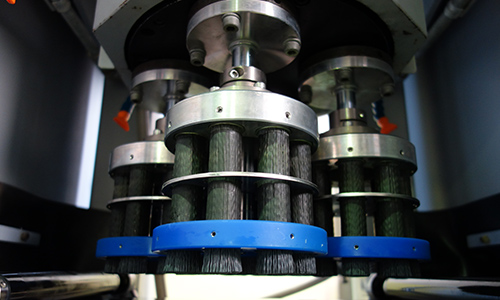

The target products and polishing media are loaded into a barrel, and by adding physical force, the products are polished through friction.

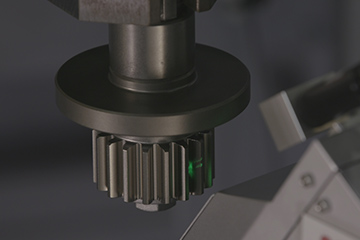

A brush is rotated at a high speed to rub the bristles against the target products for edge processing.